CSI Services – Carbon fiber composite technology partner

CSI Composite Solutions and Innovations is your composite technology partner throughout the value chain, from the earliest product development phase to spare parts supply and everything in between.

In the following chapters we provide you with a brief description of our services and views of carbon fibre composite technology specific aspects.

Carbon Fibre product development

Close cooperation keeps costs down

The major part of a product’s cost over its lifetime is determined in the product development phase. This phase is particularly important with carbon fibre composite materials, since there are so many alternatives, combinations of materials and manufacturing processes to choose from.

Choices made in the product development phase have a significant impact on the mould, material and manufacturing expenses in the serial production phase. In our experience, the best results are achieved through very close cooperation between the client and an innovative product development team with solid experience and knowledge of the most suitable materials and manufacturing techniques.

The first step in controlling a product’s cost over its lifetime is understanding its operational setting, the related requirements and the sought benefits. As our clients know their own products best, we cooperate with them during the definition phase to determine, as thoroughly and unambiguously as possible, the requirements and expectations for the product.

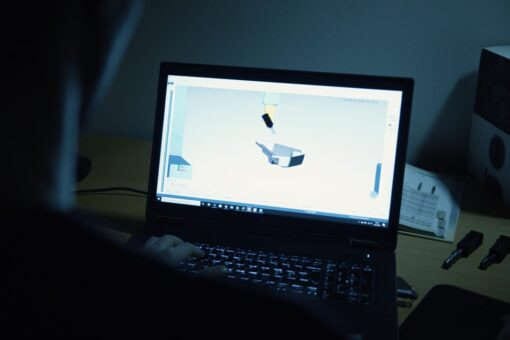

Virtual models streamline the product development phase

In product development, we always create 3D models of the products, which enable us to analyse manufacturing and raw material alternatives early on and make cost comparisons. 3D models also work as an illustrative communication aid when discussing matters such as linking the product to the rest of the structure or its appearance, trajectories and load-bearing points in different situations.

In addition to virtual models, we also manufacture physical models, partial structures and test pieces to help our clients in their decision-making process. We use cost-efficient tools and manufacturing processes to minimise expenses during the product development phase.

Design, Analysis and Tooling

Good design keeps carbon fiber product prices competitive

Designing carbon fiber composite pieces requires familiarity with the properties of the materials and the possibilities offered by different manufacturing techniques. We have extensive experience in designing various carbon fiber composite components and making strength calculations, from small injection-moulded components to large carbon fiber machine parts that comply with extreme requirements.

Product design often starts with a pre-design phase that allows us to determine important properties of the product, such as its manufacturing cost, mass and rigidity. This supports decision making when considering different carbon fiber composite materials for the new product.

We have carried out the manufacture and tool design for almost all of the products that we have made. This ensures good tool and mould functionality in our manufacturing processes, which translates to competitive carbon fiber product prices.

carbon fiber composites are the right choice because:

- In load-bearing structures, carbon fiber composites save more than 50 per cent in weight compared to steel and 30 to 40 per cent compared to aluminium.

- The strength and rigidity of a carbon fiber composite structure is carefully optimised according to load.

- The product can be given a small, negligible or negative thermal expansion.

- Natural frequencies can be set to desired levels.

- Carbon fiber enables more creative and impressive designs than conventional materials.

- The degree of integration may be increased: the fewer carbon fiber components and assembling are involved, the fewer tolerance problems occur.

- Structures can combine different materials and components: composites, metals, inserts and thread elements.

- Composite materials allow for new sizing criteria: sizing is possible for double the stretching rates in comparison to steel and aluminium.

- Composite components can reach an almost unlimited resistance to vibration and fatigue.

Serial Production and Spare Parts

Our production methods enable cost-effective serial production

Vacuum injection, resin transfer moulding (RTM) and different pressing processes, such as prepreg, sheet mould compound (SMC) and forged carbon fiber, enable us to produce carbon fibre composite products that are extremely uniform in quality and have an excellent surface quality.

Our strong know-how in computer aided manufacturing (CAM) is reflected in our use of the 3D CAD environment (SolidWorks® and CATIA®) for all our product design and analysis. We process the geometries and models to material lay-ups and machining programs.

We use a number of NC-machines in material cutting, 3-axis and 5-axis machining and routing and robotics in our in-house manufacturing processes.

We offer access to a strong cooperation network

In addition to our own manufacturing, our clients have access to a cooperation network that we use to manufacture 3D-printed or injection-moulded products and machined steel components, among others.

Quite often, components produced with the above-mentioned processes are combined with composite parts. We deliver the products to our clients in their desired format – as components, assembled or equipped.

Manufacturing methods

The following table shows our manufacturing methods and their benefits, as well as our typical carbon fiber products and material alternatives:

Vacuum

injection

Benefits of method

- one-sided, inexpensive moulds

- low material cost

- best method for large components

- good strength properties

Typical products

- typical serial size:

1–1 000 pcs/yr - unit size:

1 m × 1 m–10 m × 10 m - unit/wall thickness:

0.5 mm–15 mm

Sheet Moulding

Compound (SMC)

Benefits of method

- very fast production cycle (typically less than 10 minutes)

- high accuracy, small details, excellent surface quality

- wide range of materials available from inexpensive glass to carbon fibre

- automation of the process

- parts can be easily painted

Typical products

- typical serial size:

1 000–10 000 pcs/yr - unit size:

0.05 m × 0.05 m – 2 m × 2 m - unit/wall thickness:

2 mm – 50 mm

Resin transfer

moulding (RTM)

Benefits of method

- high measurement accuracy

- all surfaces are mould surfaces

- enables manufacturing net-size components that do not require further machining

- allows for the manufacture of very thick laminates

- enables manufacturing forms with a small radius

Typical products

- typical serial size:

100 – 5 000 pcs/yr - unit size:

0.1 m × 0.1 m – 2 m × 2 m - unit/wall thickness:

2 mm–100 mm

Forged

Carbon

Benefits of method

- fast production cycle

- attractive visual look

- adaptable for complex geometries

- excellent strength properties

Typical products

- typical serial size:

100 – 10 000 pcs/yr - unit size:

from 0.05 m × 0.05 m – 2 m × 2 m - unit/wall thickness:

2 mm – 50 mm

Filament

winding

Benefits of method

- effective manufacturing process

- excellent manufacturing process for solids of revolution

- freedom to direct strength properties

- semi-automated by nature

- ow material cost

Typical products

- typical serial size:

50–50 000 pcs/yr - unit size:

0.01 m × 2 m diam – 0.05 m × 12 m (L) - unit/wall thickness:

between 1 mm–200 mm

Prepreg

compression

Benefits of method

- best strength properties

- high measurement accuracy

- best orientation possibilities of strength properties (optimisation)

- highly customisable thermal expansion/thermal conductivity

- excellent surface quality

Typical products

- typical serial size:

100 – 10 000 pcs/yr - unit size:

0.1 m × 0.1 m – 2 m × 4 m - unit/wall thickness:

0.5 mm – 20 mm

These features apply to all manufacturing methods:

Reinforcements and fillers

carbon fibre, fibreglass, Kevlar

fillers:

cells, PVC foam, epoxy and urethane injection foams, pounce (electrical conductivity)